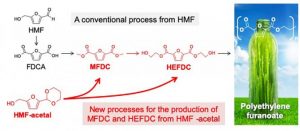

While the plant-derived polyethylene furanoate (PEF) has shown promise as a replacement for plastic polyethylene terephthalate (PET), large-scale PEF production has to date been a multi-step process that also created huge amounts of solid byproducts.

But scientists at Hokkaido University and Eindhoven University of Technology in the Netherlands, working on a joint study with Mitsubishi Chemical Corporation, have come up with a one-step method of creating biobased, plant-derived plastic monomers that will contribute towards the realization of sustainable ‘green products’ and could enable mass production of a sustainable alternative to petroleum-based materials.

Reaction pathway for the production of MFDC and HEFDC from HMF (a conventional process) and HMF-acetal (new one-pot processes). Credit: Kiyotaka Nakajima, Hokkaido University

Using a gold nanoparticle catalyst, the researchers have come up with a method that has “fewer reaction steps, and the use of highly concentrated solutions will require less energy than conventional processes.”

The researchers expect the new technique will not only improve the feasibility of commercial PEF production in the chemical industry but also help advance a more ubiquitous use of bioplastics, as well as provide insight for the development of other bio-based chemical applications from various biomass-derived carbohydrates.

Biobased plastics are emerging as a next-generation material and are expected to replace petroleum-derived plastics. In 2010 plastics manufacturing accounted for 2.7% of the country’s petroleum consumption, according to the U.S. Energy Information Agency.

Source: Hokkaido University