Over the past few years, supply chains have had virtually everything thrown at them: tariffs, a pandemic, inflation, transportation/logistics nightmares, inability to find staff, and even war. For the most part, these disruptions came out of nowhere, suddenly causing devastating results. This dynamic environment has challenged the post-professional and advanced procurement teams—what is it doing to the rest? Are we doing enough or falling back consistently to “planning” vs. implementation?

The New Normal

Besides chaos, what is normal today?

- The pandemic continues to rear its ugly head

- Russian troops are still in Ukraine

- Procurement professionals have a chance to be real heroes.

Chaos seems to be the only certainty and reducing exposure to demand, supply, and environmental risk must take priority. There are a variety of approaches. For some, this is reshoring, outsourcing, disaster planning, establishing multiple sources, automation, minimizing distances traveled, finding opportunities for greater collaboration, and the digitization of supply chains is gaining traction as is don’t touch supply chain strategies.

Procurement pros work in high-stress and demanding situations, handling everything from widespread shortages, stoppages, transportation challenges, supply-demand gaps, and disasters of every kind. Here’s the rub. We keep hearing that they should have a seat at the boardroom table. Will they insist and then take that seat?

The digital supply chain delivers real-time visibility resulting in real-time analysis, decision making, and the ability to respond fast. This digitization is an essential weapon in risk mitigation—and it must be implemented. But what is the truth about where we are?

The Shocking Truth

There’s a disconnect between what companies say they will do and what they’re doing. And the gap is sometimes enormous.

For example, Interos recently released ‘Resilience 2022,’ the second edition of the company’s Annual Global Supply Chain Report. Surveying more than 1,500 global supply chain leaders addressed the impact of continued supply chain upheavals across multiple industries—and the cost of the disruptions–$182 million in lost revenue.

Key findings of the Interos Resilience 2022 survey highlight the gaps.

- Only 11% of organizations currently monitor supplier risk continuously

- 86% of companies acknowledge that their supply chain is too concentrated given the many dangers, and more than 50% said they planned to nearshore to bring their supplies closer to their operations

- 64% of companies plan to make wholesale changes to their supply chain footprint

- 77% plan to implement or introduce technology in the next 12 months to gain visibility into their supply chains

- Only 19% currently have supply chain technology solutions implemented. But the urgency to adopt these is clear, as over 75% of survey respondents said they plan to implement them over the next 12 months.

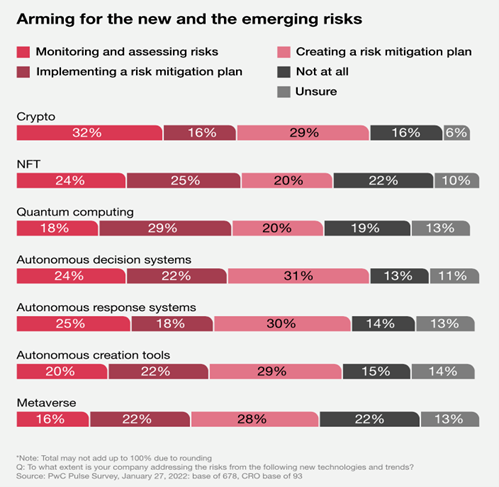

A PwC Pulse Survey performed in January 2022 surveyed 93 Fortune 1000 and private company risk leaders regarding business priorities in 2022. In this case, there is substantial action. However, the actual implementation vs. “in the process of creating” or doing nothing is still a low number, primarily representing this group.

What’s my point? These and other surveys exist, and the findings are virtually the same. Few are doing what they should be to ensure real change. They talk about plans—but implementation continues to slip. With 19% of those surveyed by Interos using technology implementations, is it reasonable to believe that 75% that claim they will implement in the next 12 months will do so? I’d bet on next year’s survey looking not much better than this year.

So, it’s no longer prudent to wait in the proverbial wings. Fortunately, the time to make real changes is when everyone is wringing their hands or throwing them up in the air—when the chaos is real and dangerous. This is going to be on you to push through—to rally the company, to get them off of dead center.

Those with the foresight to become genuinely proactive in attacking and implementing will become the industry’s experts and take a seat in that boardroom. It’s time.