By Carolyn Mathas

Historically, supply chain pros maintained top goals surrounding efficiency and cost cutting. Today, it is increasingly understood that, while cost reduction is important, it should not be the overriding goal of an organization. Professionals are now looking to tap into the vast amount of data already at their fingertips to ensure their long-term success.

In order to remain competitive, it’s the creation of value that will both attract and retain customers. Harnessing big data provides an opportunity to gain real-time knowledge, increased reliability and greater performance from the constant input of multiple sources. The resulting in-depth insights and the value created set companies and their supply chain management professionals apart.

Big Data and Value Creation

Big data analytics enables supply chain organizations to improve the way they respond to both volatile demand and supply chain risk. Advances in the Internet of Things, robotics, the mobile Internet and 3D printing have yielded amazing information capable of disrupting the supply-chain status quo.

Big data provides actionable business information from suppliers, purchasing, manufacturing, logistics, marketing and more, that deliver risk mitigation, efficiency, greater profitability and ultimately enhanced customer satisfaction.

The landscape that big data incorporates includes factors such as evaluating suppliers, sourcing channel options, integration, traceability, negotiations, capacity constraints, workforce analytics, inventory optimization, pricing, geographic location, transportation routing and scheduling and predictive asset maintenance. It also highlights previous customer demand and behavior and predicts future customer actions and response. Big data assists in establishing more responsive supply chains based on strategies involving market trends and supply-chain-related activities.

Where Are We Now?

According to a The Hackett Group study, Analytics: Laying the Foundation for Supply Chain Digital Transformation, while 94% of supply chain leaders said that digital transformation would fundamentally change supply chains in 2018, only 44% had a strategy ready and approximately 17% had implemented the use of big data to their supply chain.

Logging data, greater access to information via the IoT, and real-time information speed are already there. The analysis is the rub. Such analytic techniques as machine learning, data mining, visualization technologies required for pattern recognition, continue to rapidly evolve.

How does one go from zero implementation to mastery? Most likely through third-party partners that are already adept at gathering data, analyzing it and are especially skilled at recognizing anomalies. The creation of an effective, accurate and timely effort is not an easy task. Should the data relied on be inaccurate, creating value and enhancing customer satisfaction will be very far from the actual results.

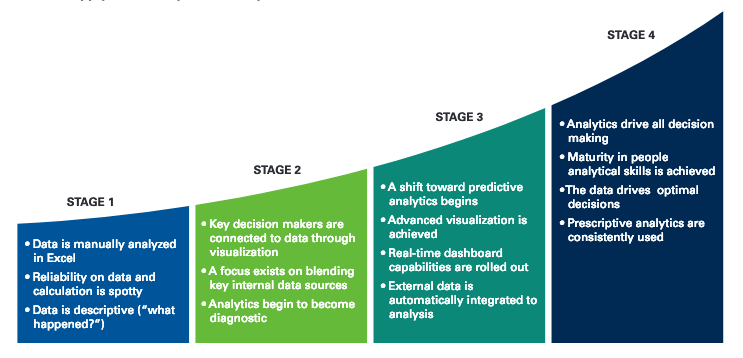

Figure 1. Supply Chain Analytics Maturity Model – Source: The Hackett Group

Why Act?

The impact of politics globally over the past few years should be sufficient evidence that companies need to be able to shift their strategy on the fly. Protectionism vs. globalization, tax code changes, fees, tariffs and impact of immigration policies are considerations that require rapid supply-chain response based on real information.

The benefits of implementing a big-data approach are clear when corporate philosophy, technology investment and establishing a customer-based approach are front and center.

Key Considerations:

- Buy-in from many organizational sectors including sales, finance, research and development, customer support, will be necessary. Supply chain professionals will need to communicate, negotiate and work well with the department heads to enable enterprise-wide improvements based on big-data analytics.

- Rapid advances in machine learning, robotics, AI and automation are the foundation of a supply chain to the future. The higher the number of data connections, and the ability to truly analyze information collected are critical to remaining competitive.

- Creating value for customers by providing them access to data including real time tracking capabilities, customers can achieve cost-saving benefits from your big data efforts. Not only will they appreciate the value created, increased customer retention is likely.

Supply chain information has been used as a reactive means of impacting the bottom line for some time. That’s no longer enough. There are amazing advantages to harnessing big data to provide internal and external value. Maintaining a competitive advantage in a rapidly moving environment is critical.

It is today’s supply chain professionals that are expected to build supply chains to maximize efficiency, reduce risk and cost, and deliver accurate, predictive and actionable results. Implementation of less than 20% will not be true for long.