North Carolina-based Honeywell has recently announced the creation of an advanced technology center of excellence in Pittsburgh to focus on innovating and developing artificial intelligence, machine learning, computer vision and advanced robotics for use across supply chains.

With more and more companies looking to automated solutions, software, and robotics to deliver increased speed, accuracy and throughput in complex material handling environments, Honeywell Robotics hopes to help shape the warehouse and distribution center of the future.

“We are bringing together some of the brightest minds, partnerships and industry collaborations to create breakthrough technological advancements for customers of all sizes, helping meet the ever-changing demands of consumers,” said Pieter Krynauw, president of Honeywell Intelligrated.

Consumer expectations have caused a seismic shift in supply chain operations. According to eMarketer, online shopping currently accounts for nearly 15% of total retail sales and is expected to grow to 22% by 2023, representing over $6.5 trillion in sales.

Online purchasing, combined with same- or next-day delivery options, has stressed the labor market to the point of a shortage. Nearly 80% of distribution center operations are still performed manually, according to DHL’s Robotics in Logistics Study. With industry growth outpacing the labor pool by a rate of 6 to 1, this growth is creating significant opportunities to automate supply chains.

The new center of excellence will be led by Joseph Lui, a robotics leader with expertise in digital data, autonomous technologies and the industrial Internet of Things. He previously served as Director of Industrial IoT and Automation Technologies, Robotics for Amazon.

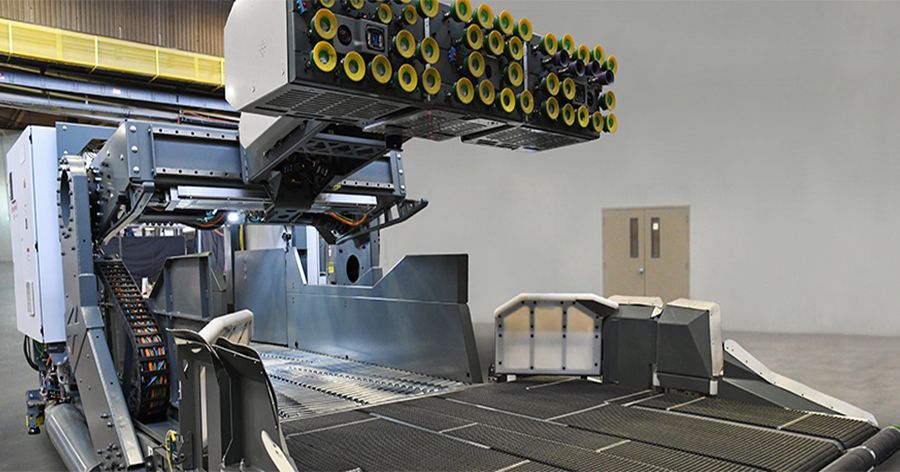

“As AI, machine learning and computer vision become commonplace, Honeywell Robotics will create innovative, breakthrough technologies to help customers alleviate skilled labor shortages, reduce safety risks and eliminate inefficient tasks,” said Lui. “The use of technology—including advanced warehouse execution systems, 3D storage and sortation solutions to improve capacity and efficiency, and autonomous mobile robots—is just the start of the digital transformation in warehouses.”

Honeywell already has a warehouse execution system that offers a configurable enterprise software platform to orchestrate equipment, labor and inventory for distribution centers. It streamlines the deployment and integration of advanced robotics by providing warehouse managers with a single, centralized system to manage their operations and automation technology.

The establishment of the robotics center of excellence is the continuation of Honeywell’s technology transformation, putting significant investment in partnerships with software vendors, universities, startups and incubators to create new solutions for industrial customers with both simple and complex needs.

Honeywell also is collaborating with AI researchers at Carnegie Mellon University’s National Robotics Engineering Center to develop breakthrough robotics technologies for distribution centers. The company, through its Honeywell Ventures investment fund, has strategic investments in robotics companies, including Soft Robotics and Attabotics, to help automate complex tasks in dynamic environments to maximize productivity and labor efficiency.

Source: Honeywell