Supply chains are far from out of the proverbial woods. For example, according to KPMG, “71% of global companies highlight raw material costs as their number one supply chain threat for 2023.” Expectations are that shortages of fuel/diesel, timber, steel, resin and plastic for packaging, adhesives, and raw materials for energy production will continue. Copper and nickel for electronic device wiring and lithium-ion battery use still have low inventories.

There are many reasons for the shortages: the war in Ukraine, higher demand in the manufacturing sector, and shipping limitations, including container shortages and delays at ports.

While shortages will always be virtually impossible to predict, some can be prevented with good planning. This planning should include:

- Work on relationships with existing suppliers, maintaining consistent communication, access to inventory levels and performance metrics, and controlling early deliveries

- Identify suppliers that have free capacities and alternative raw materials, especially in regions you are currently not tapping into

- Identify a second supply source so that you have a solid safety net in place if existing suppliers do not perform

- Although it’s counterintuitive, if you place too much emphasis on cost alone, the results may include longer lead times, lower product quality, and strained supplier relationships. Although lower costs can be significant, a comprehensive approach can bolster supplier flexibility and risk management

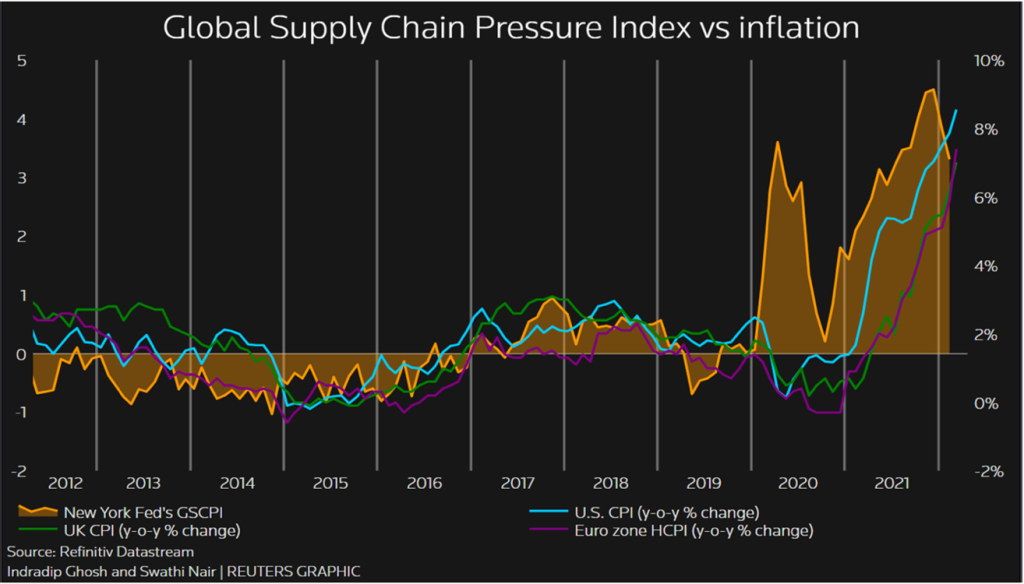

The shortages of materials naturally result in higher costs. Inflation affects supply chains, driving direct costs for materials as well as labor, energy, and transportation. Increased costs are seen in manufacturing and storage. When inflation hits supply chains and costs rise, it creates even more inflation and higher prices.

The effects of inflation on supply chains include:

- Greater complexity in procurement

- High fuel prices significantly impact logistics, driving higher transportation and freight costs that were high based on driver labor shortages

- Port congestion and import containers are also impacted by both inflation and labor availability.

- Capacity constraints, rate and price increases, instability, longer lead times, and delayed orders are also inflation results.

- Warehouses and distribution centers are pushing rates higher as storage prices are rising monthly

- Climbing costs cause excess or surplus inventory, smaller margins, and lowered revenue.

What can you do?

Accept that it’s here, minimize its impact, and take notes. It would be nice to think that, once solved, this won’t happen again; it will. There is no sense in attacking the same problem by starting with a clean slate. Learn what’s working this time. Do that.

Rein in variable operational costs to reduce overhead wherever possible. Work tirelessly to manage your inventory levels. Consider short-term, pop-up storage offered by third-party logistics providers, or 3PL, and grounding operations rather than storing freight in ocean containers.

Implementing technology solutions enables supply chains to anticipate possible disruptions or gain real-time visibility of stock to fulfill product demand. This technology should deliver the information you require in real-time to make sound decisions. Today’s digital tools enhance supply chain visibility so that errors and inefficiency can be detected rapidly. Simulation tools, including digital twins, are helping supply chains simulate performance across a variety of scenarios, including inflation. Implementing technology for more flexibility in logistics facilitates using multiple suppliers.

High material costs and inflation are wreaking havoc on supply chains and, unfortunately, are likely to continue for the remainder of the year. Managing both effectively means doing what is necessary, stepping out of a comfort zone to initiate and implement real change, especially adding new suppliers and exploring and adopting technology solutions for the long term.