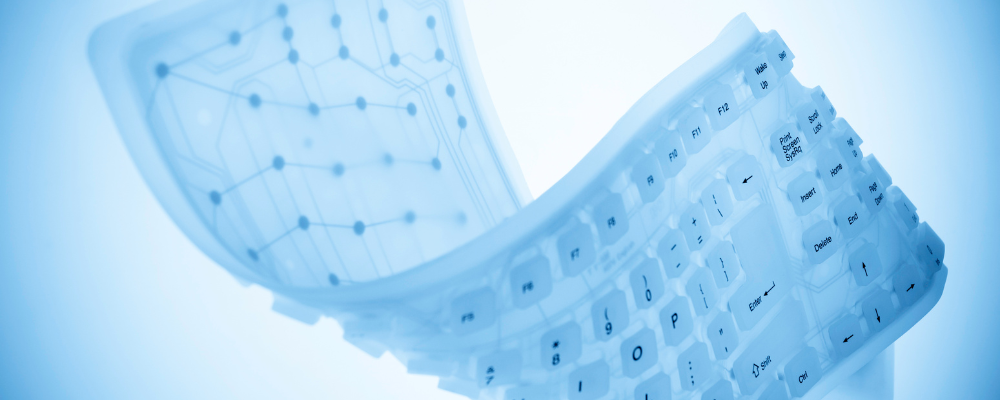

We use printed and flexible electronics in applications from energy harvesting to medical sensors to robotics. Due to their low cost, light weight, and flexibility, these hybrid electronics will continue to disrupt the market in 2023 and beyond.

One of the most exciting aspects of printed/flexible electronics is how the low-cost, lightweight, flexible form factor and compatibility with digital manufacturing can facilitate new experiences, products, and even business models. The lower cost, compared to conventional circuit boards, will enable increasingly ubiquitous electronics in applications such as smart packaging and smart buildings. They are also immensely suited for in-office and remote digital healthcare, making automotive interiors ready for autonomous vehicles, and acquiring data from industrial environments.

Interest in electronic medical patches continues to grow from respiratory monitoring of COVID patients with promises of continuous biometric tracking, early hospital release, and decentralized clinical trials, among others. Look to see improvements in the comfort and capabilities of skin patches and increased fidelity of biometric data.

Transparent antennas are incredibly well-suited for ‘connected cars,’ thin-film heaters, flexible backlighting, and capacitive touch surfaces. Look for the first release of in-mold electronics (electronics are printed and mounted onto a flat substrate that is thermoformed and injection molded) in commercial automobiles next year, as these electronics improve energy efficiency and reduce weight.

Industry 4.0 will also see significant enhancements. Greater digitization, machine learning, AI, and wireless connectivity is on the horizon as sensors become more ubiquitous, particularly as predictive maintenance and digital twins gain more widespread use. Flexible electronics will also improve inventory tracking across the board and across component sizes. Expect to see more trial projects using the unique capabilities of printed electronics.

Commercialization will continue to grow in 2023 across all technologies and applications, including use in new markets.

IDTechEx offers an extensive portfolio of technology market research reports covering many aspects of the printed/flexible electronics space. These include printed/flexible sensors, in-mold electronics, 3D electronics, materials for printed/flexible electronics, flexible hybrid electronics, conductive inks, flexible electronics in healthcare, and more.