With players in the printed electronics industry looking for opportunities to create strongly tech-focused value-add for applications, the market is changing rapidly while keeping pace with tech innovation. Some niche focuses include utilizing inkjet printing as a small part of the process of producing etched circuit boards, replacing five process steps with one, and reducing material consumption and the time to change circuit designs. Other sector members have created new industries based on platforms such as In-Mold Electronics where there is clear added value over incumbent processes. Of course, fundamental research is still ongoing across many fronts but the order of the day is identifying specific needs and opportunities.

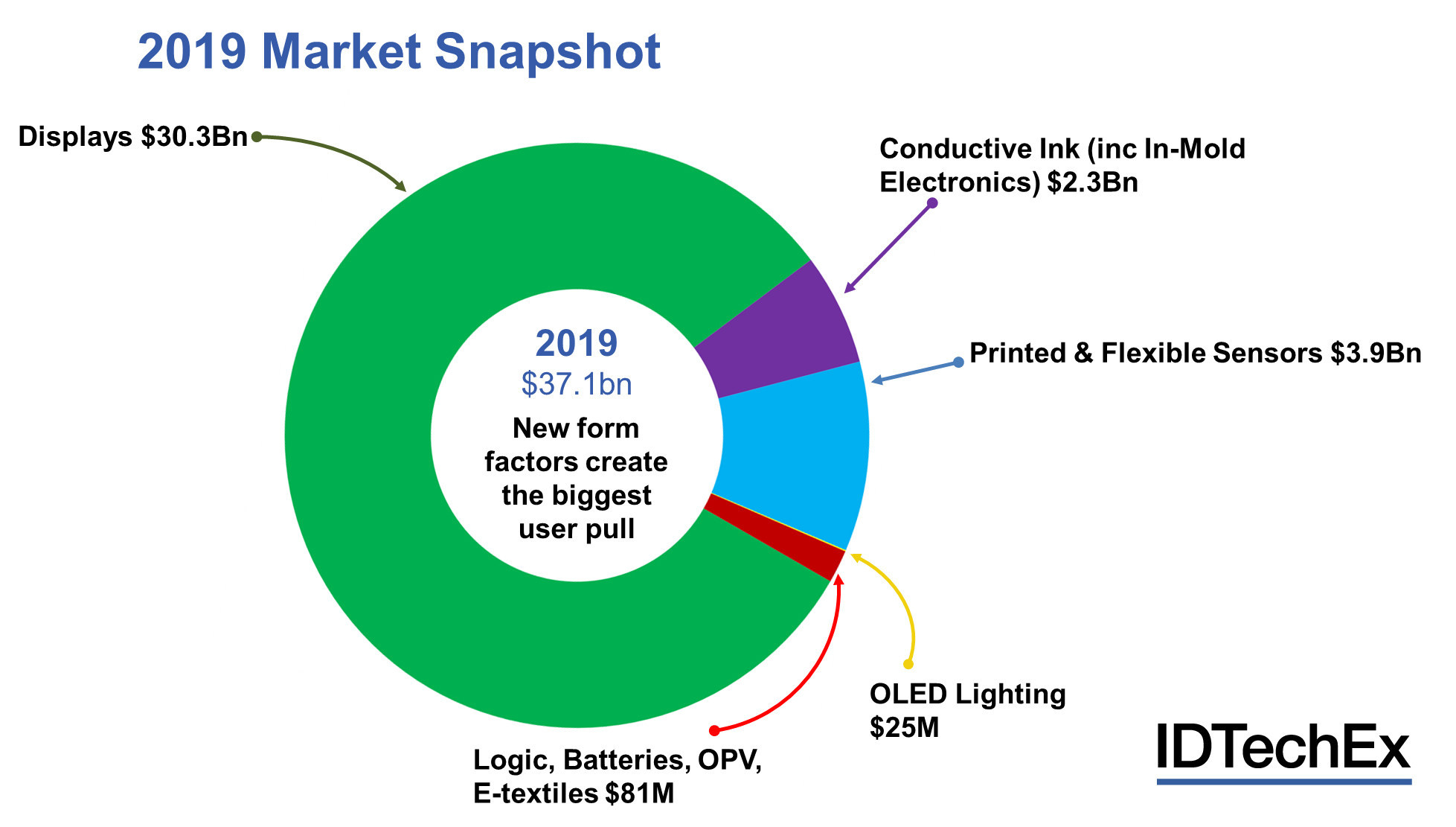

IDTechEx recently released a report on the printed, organic and flexible electronics industry, split by component type. The report, “Printed, Organic and Flexible Electronics 2020-2030,” provides a complete and detailed assessment of the entire industry. This looks at the big picture, not just printed devices but also those which may be flexible or based on functional organic materials.

Five Key Trends in Printed Electronics 2019

In-Mold Electronics gains momentum

In-Mold Electronics (IME) is a subset of structural electronics—ultimately 3D electronics with benefits including less components to integrate, faster turnaround times, ease of design and light-weighting. It is also cost-competitive. The 2019 market for IME is $5.6 million—barely a market—but one which IDTechEx expects to grow to over $1 billion in 2029. With strong engagement from automotive and white goods appliance makers to use IME for human machine interfaces, adoption is mostly hindered by scale up and reliability testing proof which is rapidly being worked through.

5G and electric vehicles create new markets for conductive inks

The increasing interest and inevitable move to 5G poses new material opportunities, in particular for electromagnetic (EMI) shielding due to the higher frequencies employed by 5G. IC plating can be slow, relatively expensive and difficult to get good coverage on all sides of the IC package. This is being targeted by those in conductive inks.

The adoption of electric vehicles means the greater use of power semiconductors. Here heat dissipation and management is an issue, and therefore printable thermal interface materials represent a large emerging opportunity and not just for power semiconductors in vehicles but also in other applications such as high power LEDs.

Component providers move downstream in search of niches

Printed or flexible components with new capabilities do not always replace existing components on a like-for-like basis, unless there is a problem with the existing component. Often they enable new things to be done thanks to their new attributes. In this case, the supplier of such a novel component is not just inventing the component but also often needs to get involved in inventing the product and demonstrating the market demand. Numerous companies have therefore moved downstream, from creating electronic skin patches using flexible printed batteries to warehouse management systems using printed flexible organic photodetector strips.

Healthcare, healthcare, healthcare

The ability to utilize flexible and stretchable electronics is being increasingly utilized by the healthcare and related wellness industry. Consumer electronics companies are pivoting their wearable technology devices to being more focused on healthcare. The market for medical wearables over the coming five years will grow faster than the overall wearable technology market.

Companies are exploiting new form factors of electronics—such as stretchable sensors—to create increased user comfort while providing ongoing actionable data. Significant developments in gas sensors, enabled by materials such as graphene and carbon nanotubes, can maximize the benefit of utilizing the many biomarkers in breath, which is also an unobtrusive detection method versus alternatives.

Fixing hybrid electronics

Hybrid electronics—the mixture of conventional components and flexible or printed electronics components where needed—can bring the best of both worlds. However, there are several bottlenecks, which have mostly been treated as afterthoughts but are now holding back volume use. Examples include the need for conductive adhesives to attach components that can be cured at low temperature to utilize low temperature substrates and having high speed automated equipment to handle the many different shapes and formats of components and assemble these. These issues are still works in progress, but so far 2019 has seen some of these hurdles being broken down, which will open up more use cases.

Source: IDTechEx