Although sustainability is evidenced in efficient and sustainable electrified vehicles, there is still substantial waste in the automotive supply chain. Approximately 75% of CO2 emissions generated by the automotive industry are from a car’s operation over its lifetime, however 18% comes from the supply chain.

Packaging is often overlooked as a major source of waste in car production. Given that the average vehicle contains over 20,000 parts from thousands of different suppliers globally, the amount of packaging created is substantial.

Moving to reusable-pooled packaging is far less costly both environmentally and economically. Real sustainability benefits for the whole automotive industry come from moving to a more circular, collaborative mindset that shares and reuses resources wherever it can.

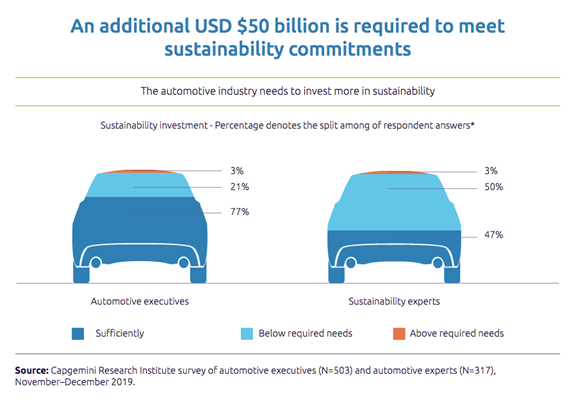

The Capgemini 2020 report on sustainability in the automotive industry identifies bringing circular economy practices across the value chain as critical to environmental sustainability.

CHEP, a provider of pooling solutions for supply chains and its automotive customers become part of its global reusable packaging network. CHEP-maintained reusable packaging is also designed to be more robust than cardboard, and far more suitable for moving onto and across automated production lines. Packaging supply is always guaranteed, regardless of the demand fluctuations, reducing wasted warehouse space.

CHEP’s end-to-end supply chain visibility means they can find transport collaboration opportunities including tracking solutions to take the risk and inefficiency out of transporting high-value or critical parts.

Original Release: Supply Chain Dive