Under the Trump administration, tariffs and trade wars are highlighting a more protectionist trade philosophy, geographical supply risks and wide-spread political risks.

Mitigating risk in the current trade climate involves identifying alternative supply sources, creating a mission-critical supply chain contingency plan, maintaining a constant eye to potential political changes and posessing a willingness to step outside of traditional approaches to risk management. Above all, mitigation requires the ability to move rapidly to offset risks that have not been part of the agenda until recently.

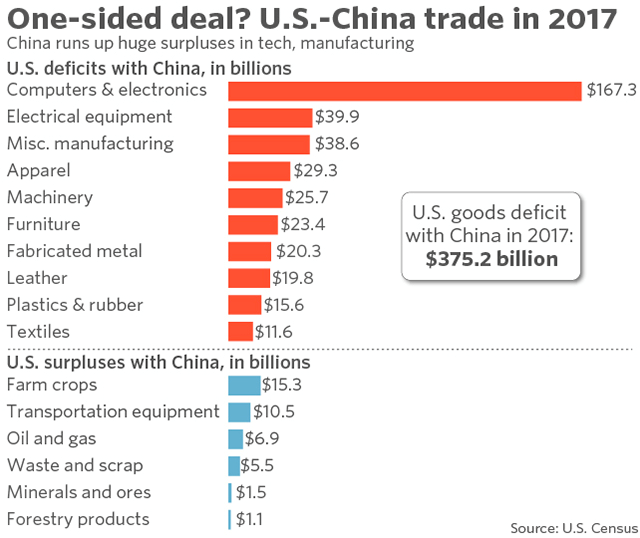

An obvious trade imbalance prompted the current administration to move from globalism to a more protectionist stance. Source: MarketWatch/U.S. Census

What are the impacts of trade wars and tariffs? Here are just a few:

The major issue is one of unpredictability. When tariffs are imposed, retaliation looms, border taxes are threatened and trade agreements are subject to modification. It’s not just difficult to adequately

- With a high reliance on China, technology companies are increasingly sourcing from potentially safer sources, primarily in the Americas

- Trade agreements are being renegotiated adding confusion and sometimes resentment

- In a climate of increasing tariffs outsourcing to cut manufacturing costs may increase quality compliance, sustainability and even ethics challenges

- Protectionism vs. a global approach and the potential for retaliatory responses, changes the playing field…potentially for a long time to come

The top risks at the forefront today include geopolitical developments, cybersecurity, and implementation of technology that can ease risk identification and mitigation.

Risk Mitigation

Recent examples of supply chain risks include increased costs of raw materials and other supply chain costs that are passed down to consumers. Given the tariffs imposed on steel and aluminum by this administration, for example, retaliatory tariffs from trade partners are the result, necessitating a migration to regional solutions delivering just-in-time supplies, often replacing long-standing global suppliers. It’s not just tariffs that cause supply chains to recruit new suppliers. Global events such as Brexit, when on March 29, 2019, the UK departs from the European Union, will cause additional supply relocation efforts.

All supply chain leaders have a responsibility to put their companies in a position to capitalize rapidly on opportunities that arise, offsetting the negative developments that occur.

So, the question becomes, how? Possibilities include:

- Evaluate and expand your current supply chain to offset potential geographic and geopolitical damage.

- Audit not only your current supply chain but your selection process, retention goals and the effectiveness of the current relationships with the supply chain, making sure our evaluation criteria is yielding the information you need.

- Review and re-adjust the supply chain no less than annually.

- Enhance possibilities to become even more adaptive via technology. Look at each link in the chain as to data exchange, flexibility, reliability

and transparency. - Implement next-generation technologies including analytics, the IoT, robotics

and automation that offset increased costs. - Implement greater security and enhanced capabilities to identify anomalies as soon as they happen.

Future proofing any organization also involves a grasp of advanced technologies and, if used, what they have the potential to deliver. Trends today strongly point to artificial intelligence and machine learning. If your company is small to medium in size and the investment into such technologies is predictably prohibitive, make sure you can evaluate the data that you do generate. Consider a collaborative partner to help establish and achieve reasonable goals over time with capabilities in the implementation of anomaly detection and analytics that focus on exactly what you need to know.

Summary

There will always be predictable and not-so-predictable supply-chain risks. Administrations will come and go, but their impact can be felt often for a considerable period of time. In a perfect world, trade agreements benefit all parties, alliances grow economies more rapidly and supply chains remain nimble enough to tackle whatever challenges they meet.

The world, however, is far from perfect. Politics, economies, cybersecurity, terrorism and even the increased number of natural disasters are all realities that can cause wild swings in risk rather than the predictability we’ve been used to. Mitigating supply chain risks within this landscape will take more knowledge, commitment and smarter use of resources than ever before.